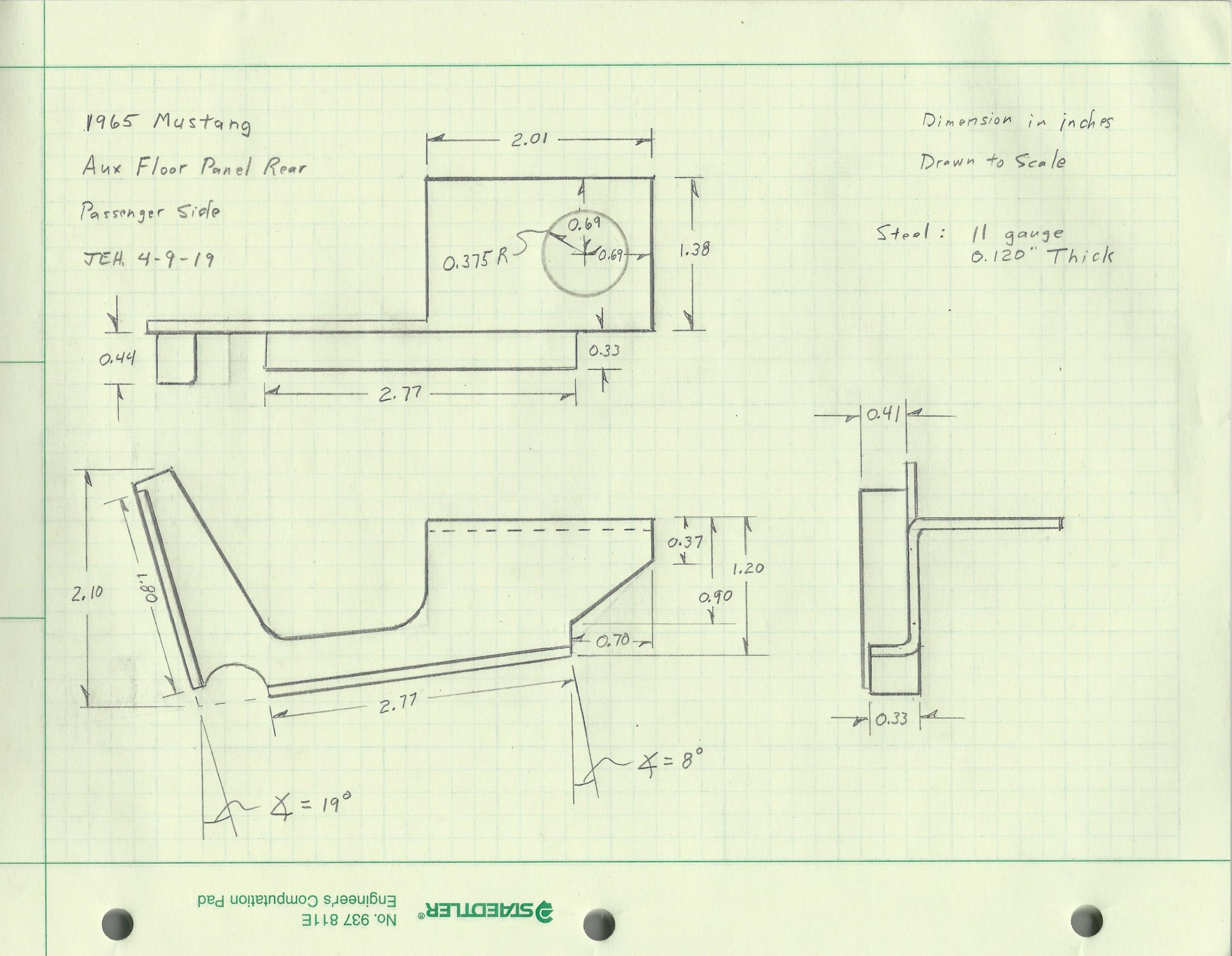

By the way Corey - CAD modeling that piece is pretty cool. Can you reverse the design to model the driver side, too?

Maybe Dynomax can use the files to create billet pieces!

Maybe Dynomax can use the files to create billet pieces!

SAAC Member Badges are NOW available. Make your request through saac.memberlodge.com to validate membership.

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Show posts Menu

)

)