Color Code Information Wanted

Ford 2100/4100 Carburetor "Support" (a.k.a. booster, cluster) Color Codes

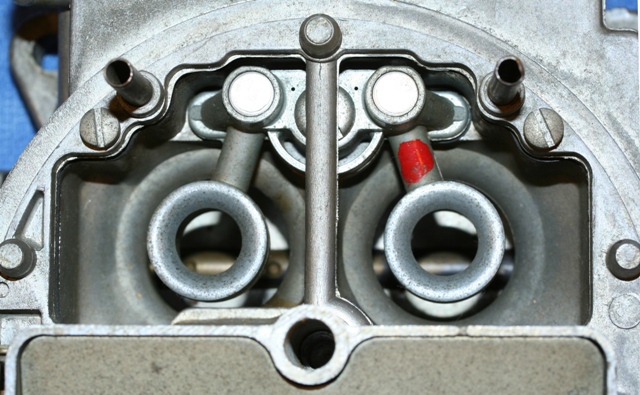

Mid 1960s support assemblies were marked with either one or two daubs of colored paint. Some of the late 1950s parts were partially dipped in dyes of different colors. The tubular passages from their tower like main bodies out to auxiliary venturi were targets for color code daubs. Each color they had could be used alone of in combinations with itself or other colors. The example below is the secondary "B" support in a new old stock C3OF-AJ model for most 1963½ HP289 Fairlane engines. The B supports received a single red daub on what would be the driver's side tube of the car the carburetor was used in.

The "BA" support used in C4OF-AL carburetor assemblies received a red daub on both tubes. There were all kinds of colors and combinations; i.e. yellow on one side and black on the other. The one I can find no data on is the "M" support used in C4OF-AL carburetors. So far I have not found anybody that knows how they were marked. While the daubs on secondary supports often last until somebody solvent cleans the assembly the daubs on primary clusters usually got washed off pretty quickly, probably by fuel mist during choke operation.

My question to the community is, does anybody have color pictures of a new old stock M support or have a used part with traces of paint remaining? I sure would like the information to complete my spread sheet on color codes on C4OF-AL, C4OF-AT, and early C5OF-L carburetors for 1964½-65 HP289 engines.

Thanks for looking.

Dan

Ford 2100/4100 Carburetor "Support" (a.k.a. booster, cluster) Color Codes

Mid 1960s support assemblies were marked with either one or two daubs of colored paint. Some of the late 1950s parts were partially dipped in dyes of different colors. The tubular passages from their tower like main bodies out to auxiliary venturi were targets for color code daubs. Each color they had could be used alone of in combinations with itself or other colors. The example below is the secondary "B" support in a new old stock C3OF-AJ model for most 1963½ HP289 Fairlane engines. The B supports received a single red daub on what would be the driver's side tube of the car the carburetor was used in.

The "BA" support used in C4OF-AL carburetor assemblies received a red daub on both tubes. There were all kinds of colors and combinations; i.e. yellow on one side and black on the other. The one I can find no data on is the "M" support used in C4OF-AL carburetors. So far I have not found anybody that knows how they were marked. While the daubs on secondary supports often last until somebody solvent cleans the assembly the daubs on primary clusters usually got washed off pretty quickly, probably by fuel mist during choke operation.

My question to the community is, does anybody have color pictures of a new old stock M support or have a used part with traces of paint remaining? I sure would like the information to complete my spread sheet on color codes on C4OF-AL, C4OF-AT, and early C5OF-L carburetors for 1964½-65 HP289 engines.

Thanks for looking.

Dan